Wafer Sort Process Engineer

- Test Operations Department

- Penang, Malaysia

Job Description

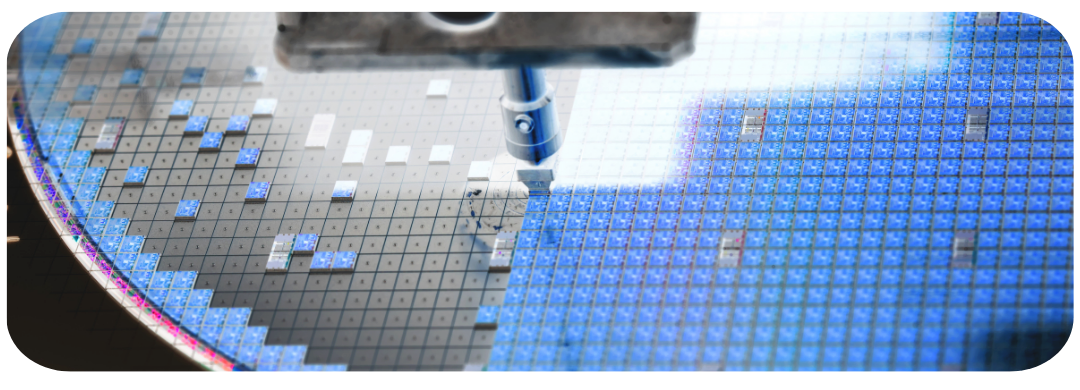

We are seeking a skilled Wafer Sort Process Engineer to join our team and play a key role in optimizing wafer sort operations at our OSAT partners. This position is ideal for an engineer with strong technical expertise in wafer test processes and a passion for driving quality, efficiency, and continuous improvement in semiconductor manufacturing.

Roles and Responsibilities

- Optimize and maintain wafer sort test processes to meet OSAT production targets for output, quality, and turnaround time

- Manage wafer sort process flow within OSAT operations, ensuring smooth handover between wafer sort and downstream

- Analyse wafer test data and yield trends to troubleshoot process issues, lead root cause investigations, and implement corrective actions to satisfy customer requirements

- Collaborate with product engineering, test engineering, quality, and equipment teams to support new product introductions (NPI) and volume ramp-ups

- Drive continuous process improvement initiatives focused on throughput increase

- Support customer audits and ensure wafer sort processes comply with OSAT quality standards (e.g., ISO, IATF) and customer-specific protocols

- Maintain process documentation, SOPs, work instructions, and training materials relevant to wafer sort operations

Qualification

- Bachelor’s degree in Electrical Engineering, Electronics Engineering, Materials Science, or related field

- Minimum 3 years of experience in wafer sort or semiconductor test process engineering

- Strong knowledge of wafer probe test equipment and wafer test methodologies

- Good understanding of semiconductor manufacturing processes, yield analysis, and statistical process control (SPC)

- Proficient with data analysis tools such as Excel, Minitab, or JMP

- Strong analytical and problem-solving skills with high attention to detail

- Excellent communication and teamwork skills

- Ability to manage multiple projects in a fast-paced manufacturing environment

- Knowledge of cleanroom protocols and safety regulations